Maxcase #16 - Mining & Mineral Process: Severe abrasion repair on pumps and valves in nickel mining processing complex.

✳️ Challenge:

Abrasive wear in pumps and valves.

✅ 🛠️ Solution:

The excessive exposure of some pumps and valves to abrasive mud from zinc processing caused severe damage to equipment, resulting in major operational loss of the entire system.

After surface preparation with abrasive sandblasting, Maxceramic 1311 coating, known for its high resistance to compression and abrasion, was used to coat the pumps and valves exposed to abrasive mud.

✅✅ Conclusions:

Equipment wear was reduced by 40% and overall system reliability improved, leading to a 20% increase in production efficiency at the complex, which returned to normal operation after equipment reassembly.

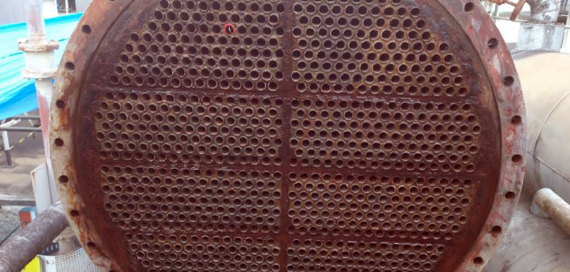

Maxcase - Gas Industry - Surface restoration, repair, and structural reinforcement of condenser mirrors affected by extreme corrosion.

Read More

Maxcase - Cement Plant - Application of ceramic-reinforced composite for structural reinforcement against severe abrasive wear.

Read More