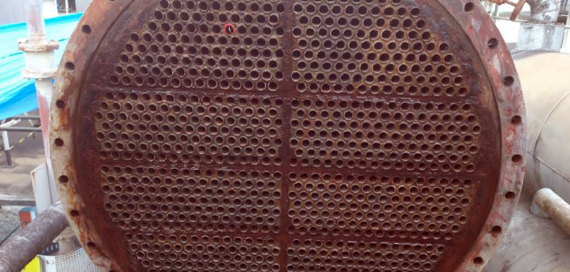

Maxcase - Gas Industry - Surface restoration, repair, and structural reinforcement of condenser mirrors affected by extreme corrosion.

✳️ Challenge: The steel surface of the mirror had its mill scale removed by corrosion, resulting in the formation of large-scale visible cavities.

🛠️ Scope of Activities:

- After cleaning the asset and removing loose particulate matter from the joint plane, abrasive blasting was performed on the surface preparation of the condenser mirror.

- It was necessary to insert 100% of the stoppers into the tubes to aid in the coating and insulation process of the mirror cavities.

-Degreaser was used to remove any impurities or contaminants from the surface, followed by the application of Max 5111 polymer to repair the joint plane, and then Max 1612 polymer to repair the remaining surface area of the mirror.

-After pre-curing, all inserted stoppers were removed.

✅ Solution: The choice of MAX1612 and MAX 5111 polymers was fundamental to achieving the result, due to their compositions with ceramic fillers for extreme corrosion (1612), in addition to resistance to compression, protection, repair and reconstruction of metals (5111).

✅✅ The repair process took only 5 days, considering the removal of all particulates and surface preparation for coating application. The choice of the aforementioned polymers, after a preliminary analysis of the situation, provided a quick recovery of the asset's surface, re-establishing acceptable thickness standards and restoring the equipment's heat exchange capacity, reducing the amount of energy consumed by the asset to maintain operation, due to the high degree of corrosion found before maintenance.

Maxcase - Cement Plant - Application of ceramic-reinforced composite for structural reinforcement against severe abrasive wear.

Read More

Maxcase - Oil & Gas - Repair and structural reinforcement of oil pipelines with composites in a petrochemical complex

Read More