Maxcase - Cement Plant - Application of ceramic-reinforced composite for structural reinforcement against severe abrasive wear.

✳️ Challenge: Wear and tear in a suction labyrinth that was badly damaged and needed to be replaced.

🛠️ Scope of Activities:

- The manufacturing time for the original part in Hardox steel was 60 days. After a technical analysis, the option was made to manufacture the part in conventional carbon steel, taking 3 days.

- After the part was manufactured, a surface preparation process was carried out to create the necessary roughness for the subsequent application of the polymer.

- Then, the Maxceramic 1211 polymer with ceramic fillers was applied, specifically developed to repair surfaces exposed to severe sliding abrasion caused by fine particles.

- The surface preparation and polymer application process took only 2 days.

✅ Solution: Manufacturing a new carbon steel part to replace the damaged component in the system, and applying a ceramic polymer for structural reinforcement.

✅✅ The repair process took only 5 days compared to 60 days if the part had been manufactured in Hardox. The total cost was approximately 50% of the cost of a part manufactured to the original specifications.

The technical choice of polymer 1211 was due to its incorporation of a unique blend of fine fillers to improve the laminar flow of the material, providing high protection against severe abrasion and corrosive environments.

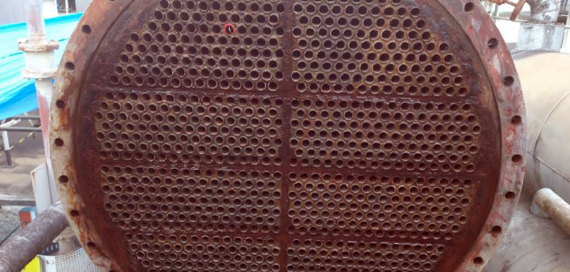

Maxcase - Gas Industry - Surface restoration, repair, and structural reinforcement of condenser mirrors affected by extreme corrosion.

Read More

Maxcase - Oil & Gas - Repair and structural reinforcement of oil pipelines with composites in a petrochemical complex

Read More