Maxcase #11 - Mining & Mineral Process: Recovery and modeling of the circumference of a liquid ring vacuum pump cover damaged by continuous operational use.

✳️ Challenge:

The equipment was found to have diametrical wear with a maximum depth of 18 mm, on around 50% of the perimeter.

🛠️ Scope of Activities:

- Surface preparation with sandblasting and electric sander to produce a rough surface;

- Application of the first layer of high-adhesion ceramic polymer Maxceramic 1511 for reconstruction;

- Assembling a template for modeling the damaged circumference;

- Carrying out two more coating applications, molding the polymer according to the template.

✅Solution:

Three applications of the coating were carried out, molding the polymer using a template. Due to the extreme damage caused by abrasion, completely incapacitating it from operating, surface preparation has become even more crucial for the successful fixation of the Maxceramic 1511 coating.

✅✅ Conclusions:

The recovery of the Nash pump cover was carried out successfully, without any anomalies, where after the curing time the template was removed and released for use.

For more...

🌐 www.maxepoxy.com

#Maxepoxy #OffshoreSolutions #IndustrialMaintenance #MaxRepairs #Distributor #SucessCases #Maxecase #MaxMetal #CaseHistories #Mining

📥 CLICK HERE TO DOWNLOAD THIS CASE.

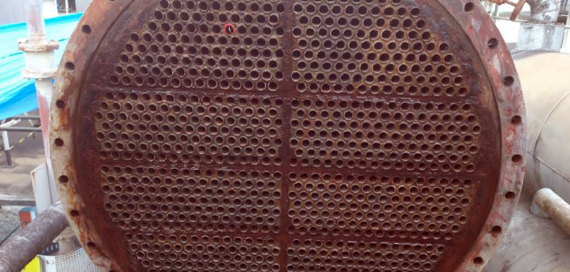

Maxcase - Gas Industry - Surface restoration, repair, and structural reinforcement of condenser mirrors affected by extreme corrosion.

Read More

Maxcase - Cement Plant - Application of ceramic-reinforced composite for structural reinforcement against severe abrasive wear.

Read More