Maxcase #08 - Water & Wastewater: Recovery and coating of pump volutes and impellers that showed wear caused by internal corrosion, cavitation and abrasion.

✳️ Challenge:

Recovery and coating of pump volutes and impellers that showed wear caused by internal corrosion, cavitation and abrasion.

🛠️ Scope of Activities:

-Surface preparation to create a roughness profile;

-Application of Max 1311 polymer to restore worn regions;

-Application of Max 1512 polymer for finishing and reinforcement.

✅Solution:

The recovery and coating service for the volutes and pump rotors took place in 3 stages: Surface preparation to create a roughness profile through abrasive blasting in accordance with an almost white metal standard (Sa 2.1/2) in accordance with NBR 7348/2007, that is, with an average roughness of at least 45 micrometers. Application of the coating, followed by the application of reinforcement to rebuild and protect surfaces subject to chemical, abrasive and corrosive wear.

✅✅ Conclusions:

The recovery and coating services for volutes and pump impellers took place as planned and achieved the established objectives. Both the rotors and the volutes, after the surface preparation process that ensured good adhesion of the polymers to the metallic substrate, had their worn surfaces recovered and also protected against the factors that caused corrosion, cavitation and abrasion processes. With the system returning to operating at full capacity and with an extended useful life.

📥 CLICK HERE TO DOWNLOAD THIS CASE.

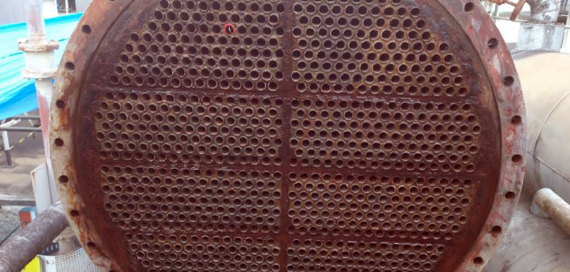

Maxcase - Gas Industry - Surface restoration, repair, and structural reinforcement of condenser mirrors affected by extreme corrosion.

Read More

Maxcase - Cement Plant - Application of ceramic-reinforced composite for structural reinforcement against severe abrasive wear.

Read More