Maxcase #01 - Mining Company: Application of coating with metallic polymers and industrial bands on 20” stainless steel pipe bends in the mining industry.

✳️ Challenge:

Three leaks were identified in the curves located close to the flange and three more welded plates with reports of leaks were identified precisely in the welding seams, affecting gas production and impacting the mining company's activities.

🛠️ Scope of Activities:

- Removal of existing coatings;

- Surface preparation of sections to be repaired;

- Application of metallic polymer MAXMETAL 5411;

- Application of metallic polymer MAXCERAMIC 2232;

- Application of industrial bandage MAXCOMP;

- Application of anti-UV paint.

✅Solution: Surface preparation on Bends A and B was conducted through abrasive blasting. Subsequently, a reconstructive job at the eroded areas was carried out with the application of our MAXMETAL 5411, followed by the application of our MAXCERAMIC 2232 for surface protection. Upon completion of this stage, additional structural reinforcement was provided with the application of our MAXCOMP wrapping systems, followed by the application of anti-UV paint.

✅✅ Conclusions: The repairs were reviewed according to the proposed scheduled dates, and the outcome met all of the client's expectations.

📥 Click here to download this case.

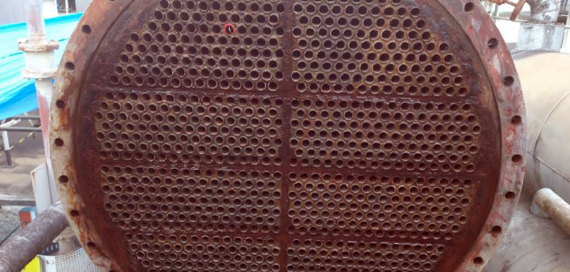

Maxcase - Gas Industry - Surface restoration, repair, and structural reinforcement of condenser mirrors affected by extreme corrosion.

Read More

Maxcase - Cement Plant - Application of ceramic-reinforced composite for structural reinforcement against severe abrasive wear.

Read More