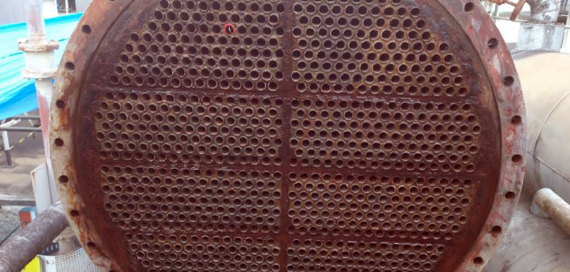

Maxcase #13 - Lack of preventive maintenance on ball mill heat exchangers, with periodic rotary mechanical cleaning, leading to loss of efficiency and high rate of perforated pipes.

✳️ Challenge:

The covers were undergoing a very intense corrosion process, classified as high grade. Requires cleaning with the removal of oxidation deposits to ensure adhesion.

🛠️ Scope of Activities and Solution:

- Dry Abrasive blasting was applied creating the necessary profile and removing any contaminants from the substrate;

- A degreaser was used to eliminate all non visible contaminants;

- Maxceramic MAX1612 was applied by brush to protect all affected areas.

✅✅ Conclusions:

After final inspection all punctured tubes were plugged, and all dividing plates and lids were protected successfully with Maxceramic MAX1612 the asset successfully returned to service right after curing.

For more...

🌐 www.maxepoxy.com

#Maxepoxy #IndustrialMaintenance #MaxRepairs #Distributor #SucessCases #Maxecase #MaxMetal #CaseHistories #Mining #Ballmill

📥 CLICK HERE TO DOWNLOAD THIS CASE.

Maxcase - Gas Industry - Surface restoration, repair, and structural reinforcement of condenser mirrors affected by extreme corrosion.

Read More

Maxcase - Cement Plant - Application of ceramic-reinforced composite for structural reinforcement against severe abrasive wear.

Read More