Maxcase #07 - Oil & Gas: Lines worn out by external corrosion causing loss of thickness, which can lead to rupture and total system failure.

✳️ Challenge:

Lines worn out by external corrosion causing loss of thickness, which can lead to rupture and total system failure

🛠️ Scope of Activities:

-Depressurization and draining of the line for repair.

-Application of abrasive blasting to clean and prepare the surface, creating the roughness necessary to adhere the coating.

-Application of MaxComp9182 composite wrapping system.

✅Solution:

Use of the MaxComp 9182 composite wrapping system, composed by an epoxy matrix reinforced with bidirectional fiberglass fabric with resistance of up to 130°, suitable for pressurized equipment and complex geometries.

✅✅ Conclusions:

During the last 3 months, the lines have been inspected by the maintenance team, with no reports of wear and pressure changes on the internal walls of the system. 330mm of Maxcomp 9182 coating were applied to 300mm of pipes.

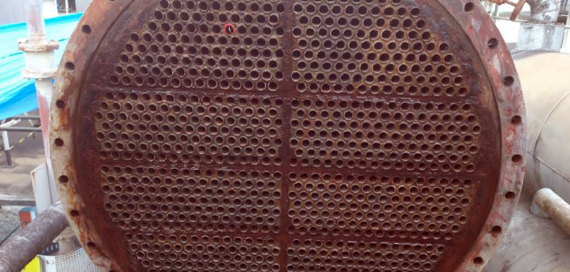

Maxcase - Gas Industry - Surface restoration, repair, and structural reinforcement of condenser mirrors affected by extreme corrosion.

Read More

Maxcase - Cement Plant - Application of ceramic-reinforced composite for structural reinforcement against severe abrasive wear.

Read More