Maxcase #15 - Oil & Gas: Application of fiberglass reinforced coating resistant to high pressures and high temperatures, in leaky gas pipes on an oil platform.

✳️ Challenge:

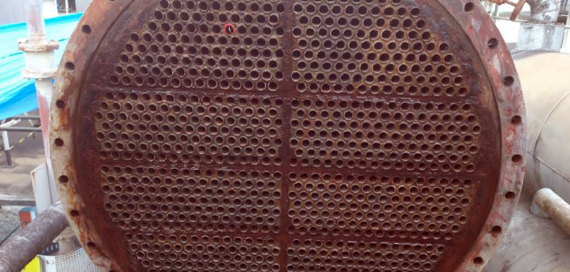

Line with major damage caused by internal and external corrosion and leakage.

✅ 🛠️ Solution:

Due to the action of time and wear caused by the sea, in addition to an attempt at a palliative repair made by the internal team, the damage to the surface of the line presented an aggressive aspect of erosion (hole), making the repair challenging, in addition to the high temperatures of the gases passing through the line.

To carry out the repairs, it was necessary to depressurize and drain the line. Then surface preparation with an abrasive jet applied to prepare the surface, leveling and creating the necessary roughness in the area of application of the coating.

And to conclude, the application of the coating with the MaxComp 9182 fiberglass fabric suitable for pressurized equipment with a high degree of corrosion.

✅✅ Conclusions:

The repairs were carried out within a few hours, and the leak was completely sealed with fiberglass lining.

The gas system returned to operation in less than 24 hours at full capacity, with the company reducing the asset's downtime, alleviating losses and returning to normal production.

This maintenance saved around 15% in replacement costs and replacement of parts of the asset.

📥 CLICK HERE TO DOWNLOAD THIS CASE.

Maxcase - Gas Industry - Surface restoration, repair, and structural reinforcement of condenser mirrors affected by extreme corrosion.

Read More

Maxcase - Cement Plant - Application of ceramic-reinforced composite for structural reinforcement against severe abrasive wear.

Read More