Maxcase - Oil & Gas (Gas line active leak) gas line was severely damaged and leaking. It required depressurization, resulting in a decrease in plant production.

✳️ Challenge: The platform's gas line was severely damaged and leaking. It required depressurization, resulting in a decrease in plant production.

🛠️ Scope of Activities:

- After careful surface preparation, Max 5361 was applied, an ultra-fast curing polymer that reduces downtime and is ideal for emergency repairs.

- Next, Max 1511 was applied, with ceramic reinforcement, smoothing the substrate's geometry.

- Finally, Maxcomp 9182 structural reinforcement restored the piping, ensuring its original operating conditions.

✅Solution: Due to the active leak, it was necessary to depressurize the line and choose a polymer solution for emergency and fast-drying repairs, combined with structural reinforcement technology with metal fillers, in addition to the application of polishing with ceramic fillers to smooth the geometry of the substrate.

✅✅ Through analysis and the correct choice of solution, the gas line returned to operating in its original state within a few hours, thus normalizing its production, gaining financially and saving time, as it was not necessary to replace the damaged section, mitigating the loss caused by a longer shutdown.

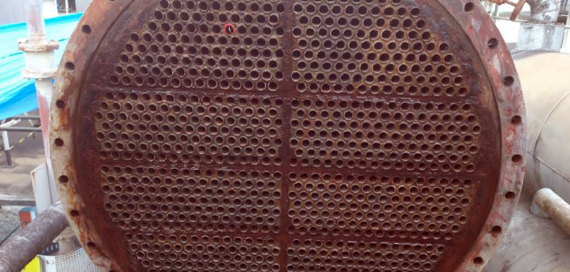

Maxcase - Gas Industry - Surface restoration, repair, and structural reinforcement of condenser mirrors affected by extreme corrosion.

Read More

Maxcase - Cement Plant - Application of ceramic-reinforced composite for structural reinforcement against severe abrasive wear.

Read More