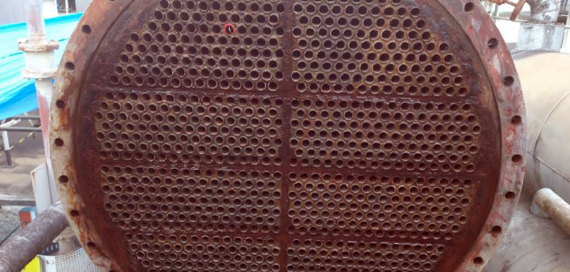

Maxcase #05 - Paper and Cellulose Factory: Several points of corrosion in 3 heat exchangers, affecting the flow rate and performance of the equipment in the short term.

✳️ Challenge:

Eliminate corrosion of heat exchangers by repairing the affected surface through the application of reconstruction and reinforcement polymers.

🛠️ Scope of Activities:

Surface preparation using blasting with abrasive material to increase roughness;

Application of Max 5411 paste polymer for filling

Application of Max 1512 liquid polymer

✅Solution:

Surface preparation by blasting with abrasive material in order to create a sufficient roughness profile to guarantee the product anchoring. Then, the MAX 5411 polymer was applied with metallic fillers for reconstruction and filling the corrosion points and, finally, the MAX 1512 polymer with ceramic fillers was applied to protect surfaces subject to wear.

✅✅ Conclusions

In 2 days, the repair, recovery and reinforcement of the heat exchangers took place as planned, with the equipment returning to operation at full capacity. Being reviewed weekly by the industry team.

📥 CLICK HERE TO DOWNLOAD THIS CASE.

Maxcase - Gas Industry - Surface restoration, repair, and structural reinforcement of condenser mirrors affected by extreme corrosion.

Read More

Maxcase - Cement Plant - Application of ceramic-reinforced composite for structural reinforcement against severe abrasive wear.

Read More